Water is a crucial resource for the existence of both planet Earth and the living beings populating it. Our bodies are made of water for the most part and 71% of the globe is covered by oceans. This particular composition, which is unique in our solar system, makes the climate, oxygen and any form of livelihood depend on water. Even if we retreated like hermits on top of a mountain we would still need oceans to survive.

For decades the preservation of our ecosystem has faced hard challenges, too often though, in the comfort of our own bubble we cannot focus the issue on a larger scale. By 2050 the quantity of plastic (by weight) in the oceans will outnumber the fish and that comes as no surprise given oceans today contain almost 86 million cubic metres of plastic, for the most part crumbled into microplastics, pieces so tiny to not be visible by the naked eye.

The “NextWave” Project

It may look like an odd link, but the connection between oceans and technology is actually very deep. In 2017, Dell Technologies saw an opportunity in ocean-bound plastic and set a long-term goal to match the circular design with the reuse of such materials.

Following this philosophy, they gave life to NextWave Plastics, a consortium made of big corporations that decided to take action and repurpose ocean-bound plastic (otherwise left to float and pollute only) by creating new products and consumer objects.

In 2023 NextWave Plastics entered its fifth year of activity counting the equivalent of 2,27 billion plastic bottles diverted from the oceans thanks to a network operating among 21 countries with specialised ocean-bound plastic suppliers that sort and manage the material to deliver Nylon 6 e 66, PET, HDPE and PP to the consortium’s organisations so they can reuse it to produce new items and packaging.

The Closed-Loop

Electronic waste has rapidly become one of the most concerning factors in the ecological landscape: just think of how many little pieces have to be puzzled together to make even one laptop. Until 2020 just 17,4% of electronic devices were documented as correctly sorted and recycled.

With this in mind, Dell Technologies decided to invest not only in long-term goals featuring circular design but also to tackle e-waste as much as possible for the older devices (and therefore devices that are more complicated to disassemble and recover) to prevent these from disappearing in the generic waste uncontrolled.

Thanks to the collaboration with Covestro, the biggest producer of polycarbonate and resin, Dell Technologies managed to introduce the concept of “closed-loop” regarding the lifecycle of a laptop. In the first experimental steps, they found that by reusing the plastics and resins of old laptops, after a grinding and blending process, the newly produced parts didn’t lose any of their strength and could reach, after a third cycle, a 72% recycled product. Considering the average lifespan of a laptop stands between 3 to 8 years, applying such cycle could extend the life of each part to 32 years.

Concept Luna

What about the new product lines? The goals in this case are just as interesting. We’re talking about “Concept Luna”, an initiative started two years ago by Dell Technologies tracing a very specific design manifesto where nothing goes to waste.

Besides an intensive usage of recycled and renewable materials such as carbon fibre, bio-rubber, bio-plastics and scraps from other industries, the focus of Concept Luna resides in the modular design of laptops, with fewer screws and adhesives and more snap pieces to allow a better disassembly or repair and an easier re-usage.

To this day, this concept is applied to more than 125 different product lines making the whole Dell Technologies’ product portfolio 90% recyclable and renewable. In addition, the organisation promotes free collection of old devices for those who don’t know how to sort them correctly.

Eco-Loop – An example of sustainable excellence

With the EcoLoop carrying bag, Dell Technologies demonstrated that ecological responsibility doesn’t stop at the electronic devices we use. To be honest, it could be quite counterproductive to own a perfectly sustainable laptop but to carry it in a bag which was produced in factories or with materials that are all but attentive to emissions.

The first big difference outlined by EcoLoop is the innovative dyeing process involved. While the majority of these processes feature the immersion of textiles in dyes with softening agents, emulsifiers, additives and various toxic chemicals, the technique used for EcoLoop employs mixing the dye directly with the polyester pellets before it becomes fibre. This can cut by 97% the amount of water used in the process.

Both the internal and external sides of the bag are made with 100% recycled polyester which once was ocean-bound plastic. The equivalent of 34 million plastic bottles has been yet diverted to produce EcoLoop, making the product eligible for the Ocean Cycle ™ certification.

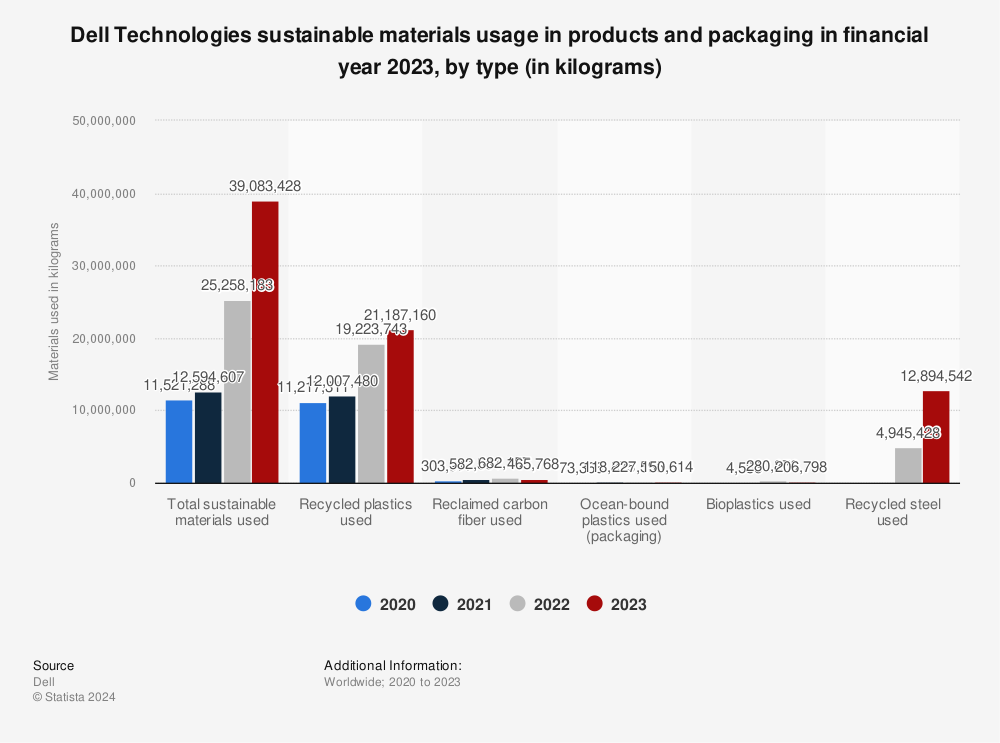

Although EcoLoop is indeed an example of excellence for Dell Technologies’ sustainability, many other items present high levels of recycled plastic in them: accessories like stands, arms, webcams, speakerphones, docking stations; Precision workstations; Latitude and XPS laptops; the packaging in which all these products are shipped.

Tech road to net zero is still a long way to go, however, it doesn’t mean goals cannot be met. The reach of awareness by many key corporates in the global economy surely determines a clear, scientific-based and well-documented path. 86% of executives consider sustainability a crucial investment in order to protect the ecosystem, the quality of our life and the organisations we work for. The time has come for us to turn tides, both for the big and small fish, each in their own water flow so it can keep on being viable without pieces of plastic all around.